| Specification | Value |

|---|---|

| Capacity | Discharging of 1 Vehicle Capacity |

| Recycling Capacity | 15 m³/h |

| Loading Hopper Dimension | 730x1200 mm |

| Height of Loading | 1670 mm |

| Height of Discharge | 2032 mm |

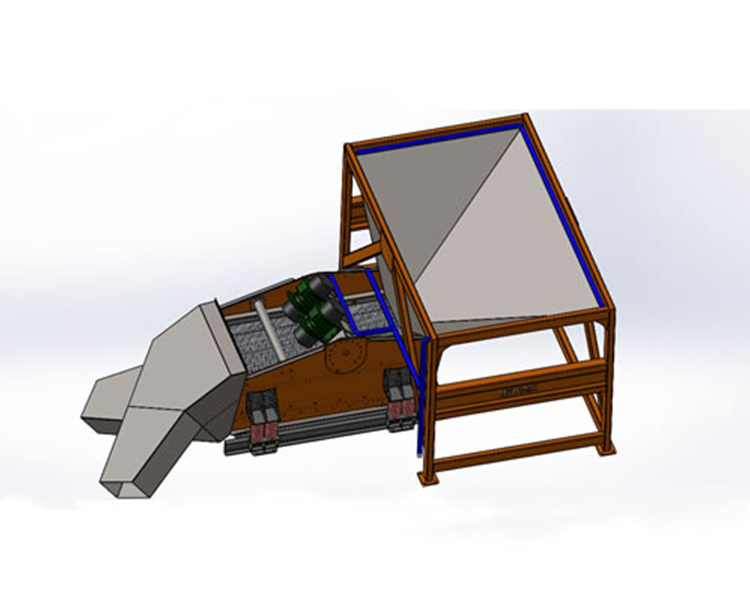

| Length of Separator screw conveyor | 5000 with hopper |

| Screw Conveyor Motor Gear-Box Power | 5.5 kW |

| Screw Conveyor Washing Pump Power | 2.2 kW |

| Screw Conveyor Washing Pump Capacity | Height 10 m, 37 m³/h |

| Recycling Pump Power | 7.5 kW |

| Recycling Pump Capacity | Height 30 m, 30 m³/h |

| Agitator Power | 5.5 kW |

| Agitator Speed | 52 rpm |

| Agitator Diameter | 1.2 m |

| Submersible Pump Maintenance Reel Capacity | 1000 Kg |

| Flowing Pipe for Recycling Water | AVAILABLE |

| Discharge Channel | AVAILABLE |

| Intake Reservoir | AVAILABLE |

What is Concrete Recycling System? How Does it Work?

Are you still throwing away your concrete wastes, wrong dispatches or defects? With Haksan concrete recycling systems you can separate the wastes into their components like aggregates, sand and water to re-use them in the production.

Nowadays, the importance of environmental responsibility continues to increase. For a cleaner world for future generations, specific rules and standards are introduced in the production of concrete. Being very sensitive to the environment, Haksan offers concrete recycling solutions along with concrete plants.

A concrete plant equipped with a recycling unit is able to re-use all the components from concrete wastes: aggregates, sand & water. It may seem like the amount per truck mixer is not much but on the long run, it may reaches high and reasonable numbers.