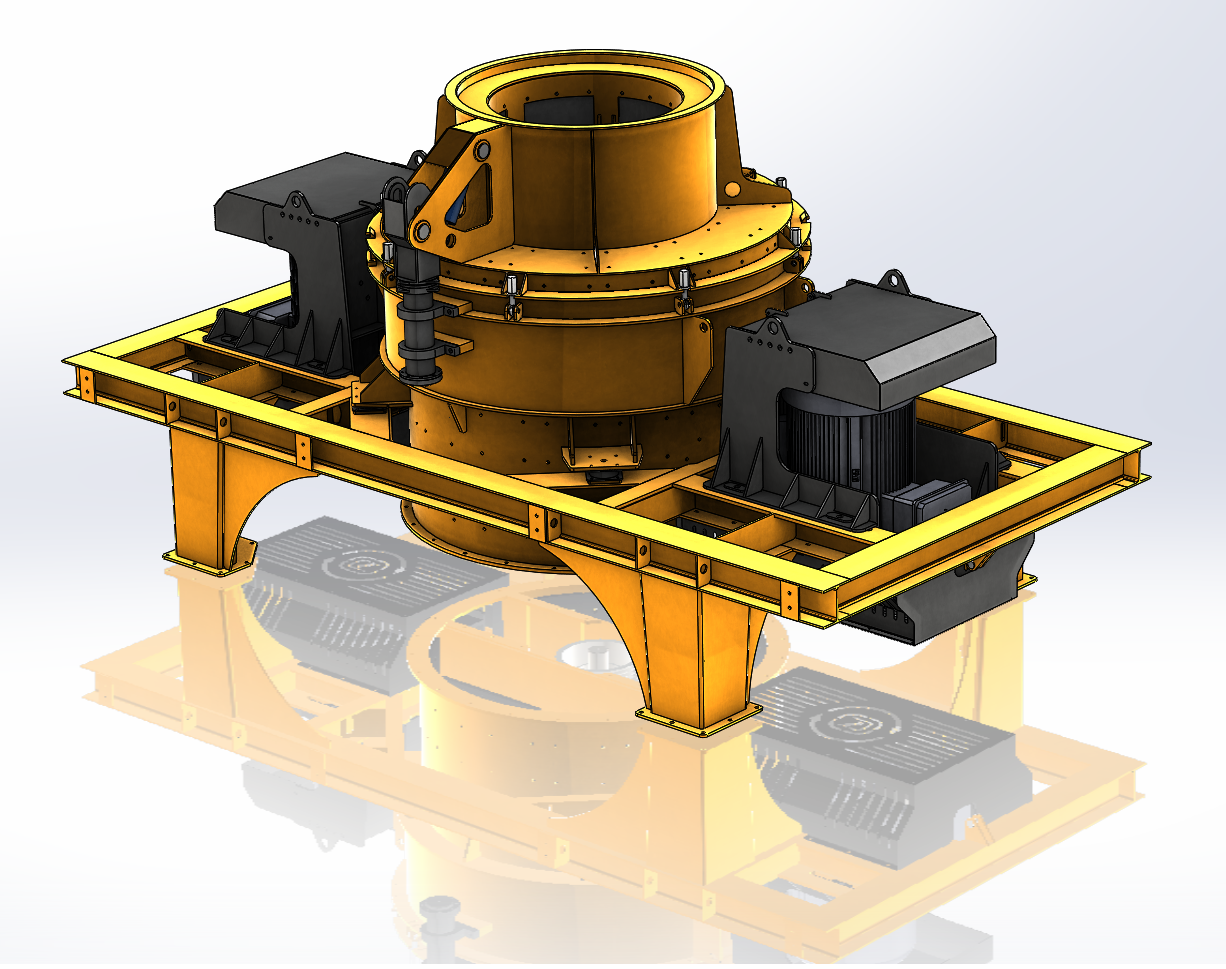

Tertiary crushers are used to make the flat material as in a cubical shape which come from Cone Crusher. This machine is produced in different combinations such as Open rotor and Anvil, Closed rotor and rock bearing.

The machine can rotate approximately 1400 rpm. Therefore, the materials flinging from the launching cells, the material in the crusher’s body are broken by hitting the materials in the pad chamber or counter crush chocks (ANVIL). Because the crushers cover will simply be opened by a hydraulic piston on the cover, machine maintenance can be performed easily.Excellent product, low wear cost, cubic, application flexibility and easy maintenance.

The machine can rotate approximately 1400 rpm. Therefore, the materials flinging from the launching cells, the material in the crusher’s body are broken by hitting the materials in the pad chamber or counter crush chocks (ANVIL). Because the crushers cover will simply be opened by a hydraulic piston on the cover, machine maintenance can be performed easily.Excellent product, low wear cost, cubic, application flexibility and easy maintenance.

Design benefits of Sarıçelik brand :

- Solution sought for stream material and basalt

- Low initial investment cost

- Robust steel construction

- Design for easy and fast installation

- Alloy steel shaft and heavy duty double row bearings in particular those supported hive

- Less service and maintenance needs

- Cubical product

- Hydraulic valve opens

- Automatic lubrication system

- Private housing and door linings